Cleaning deep fryers is essential for operators, that rely on their fryer. The best way to clean your fryer is by boiling it out.

What Does It Mean to Boil Out a Deep Fryer?

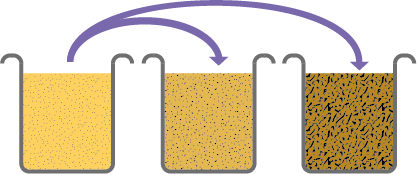

Boiling out a deep fryer is the process of removing old, degraded oil, adding water and cleaning solution, and then boiling the water to thoroughly clean the interior of the fryer and remove any oil and frying debris.

Why Should I Boil Out My Deep Fryer?

One of the main reasons operators should boil out their deep fryer is because it protects the taste of their food. Old food and dirt in your deep fryer can affect the oil, which affects the flavor of the food fried.

Boiling out your deep fryer also helps frying oil to last longer. If operators don’t boil out your fryer, there may be proteins, polar contaminants, and other materials that can affect frying oil immediately after it’s added, which causes oil to deteriorate faster. By boiling out the deep fryer, you ensure frying oil to last longer and save money on replacement costs.

If operators get into the habit of regularly boiling out their deep fryer, they will be able to use fewer chemicals, because it will prevent dirt from building up.

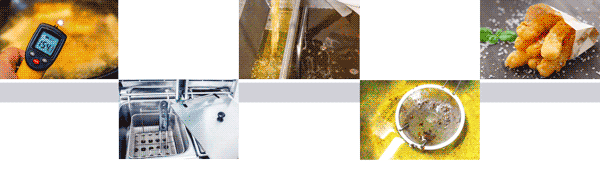

Step-by-Step Instructions

for boiling out a deep fryer

Drain all the oil from the fryer and safely, discard it via an oil caddy and an approved oil discharge container.

Use a fryer cleaning rod to clean remaining debris out of the drain line if needed.

Rinse the fryer with hot water to remove excess undrained fat.

Fill the fryer with cool water within at least 8-10 cm (3-4″) of the top. Then, add your deep fat fryer cleaner. Check the instructions on the bottle to find the specific amount you need to use. If you clean a pressure fryer, please DO NOT CLOSE THE LID!

Boil slowly as per cleaning-aid instructions.

Allow the fryer to drain slowly. When the water has drained, use a suitable fryer brush to clean the sides, top, and heating elements of the fryer.

Rinse thoroughly to remove all residue (any soaps left into the vat will quicker degrade the new oil).

Add new oil.

Note: refer to the operations manual of the fryer for safety and fryer specific information! Always wear PPE (personal protective equipment)!

Boiling out deep fryer at regular intervals can help improve the taste quality of fried food, cut down on oil replacement costs, and improve the life of your fryer. It’s a simple process that involves removing the oil, adding water, and cleaning solution, boiling until stuck-on grease and dirt come off, and finally adding in fresh oil.